Is a platform in INDIA and is partner with

CALA CASA SL Spain

Memeco NV Group Rochem – ROCHEM TECHNICAL SERVICES Germany

ECO HEALTH PRODUCTS PVT LTD

Introduction

CALA CASA SL a CALA CASA INDIA PVT LTD Partner

Cala Casa is a company established in Spain and has experience spanning nearly two decades in various projects across the world. Cala Casa has been involved in projects in Asia, Australia and Africa and has collaborated with many professional entities and groups around the world including Europe and the United States. Thus, Cala Casa brings a vast network of relationships, expertise and experience relevant to the conceptualisation, preparation and implementation of desalination, water reuse and power projects.

-a CALA CASA INDIA PVT LTD partner

Sewage treatment systems

The patented membrane bioreactor Rochem Bio-Filt® has been mainly developed for waste waters treatment thanks to its high efficiency, can be also employed for some particular functions such as containerised mobile plants and special plants for landfill leachate and industrial waste water treatment.Thanks to the modular configuration it is possible to build systems with capacities ranging from 10 to over 500m3/day in the following configurations:

- Standard

- Military (In full compliance with all international laws)</li<

- Containerised

- Custom made

- Fully automated

USING ECO-TEC PROCESS

Fresh, potable water is increasingly becoming a rare commodity, with traditional sources like rivers, lakes, tanks and ponds becoming progressively converted into cesspools of sewage. Traditional sources of fresh water like rivers, lakes and ponds have become polluted with a combination of untreated sewage, industrial effluents, outflow from leather tanning units, effluents from sugar mills, paper mills and textile units, waste water from fish processing units, etc. with dangerous levels of bacteria and a multiplicity of toxins that it is unfit for washing or irrigation, let alone drinking.

Even in places with good rainfall, poor sewage management has resulted in untreated or partially treated sewage being let out into canals and drains to be washed away by rainwater. The sewage finally ends up in the rivers, ponds, lakes or backwaters, polluting them. Quite a lot of the sewage penetrates or leaches into the soil along its circuitous journey polluting the ground water. As a result, coliform bacteria and E-coli count in ground water is alarmingly high, making the water dangerously unfit for drinking.

ECO-TEC PROCESS has been developed which is an eco- friendly technology that makes use of natural products for treating sewage, wastewater and several forms of industrial effluents and converting them into water fit for re-use. This technology can also be used for treating potable water to ensure that it is absolutely safe, germ-free and truly fit for drinking. The additional expenditure incurred in implementing this process can be more than justified by the substantial improvement in public health and the drastic reduction in the cost of medical expenditure.

The ECO-TEC PROCESS is a very simple process for treating sewage using reagents to convert it into potable grade. The process consists of two simple steps:

- Organic solid waste digestion, and

- Flocculation, sedimentation with disinfection rolled into one.

The water thus purified, after filtration through sand and carbon filters is odour-free, clear and free of harmful bacteria like E-coli and Salmonella. It is absolutely safe for re-use. The ingredients also have the unique property of de-scaling pipes. As such, it makes this treated water ideal for industrial use, particularly in boilers and AC plants.

The sludge is minimal and whatever sludge gets precipitated can be pumped out, dried and used as a very effective nitrogenous manure.

The process involves the use of:

-

- E- DIGEST : An organic sludge digester that destroys 80% of the solid wastes in the sewage, while controlling the foul odour caused by gases like Hydrogen Sulphide, Ammonia and Methane. The dosing required is marginal – 5 ppm.

- E- CLEAN- : A proprietary reagent prepared from natural extracts that flocculates and sediments sludge within minutes of dosing while also eliminating all the harmful bacteria.

Once filtered through a disc filter or a combination of glass media filter and activated carbon filters, the treated water is fit for re-use. Being of natural origin, the reagent and the treated water are totally non-toxic and safe. They have no unpleasant taste or irritating smell.

Implementation of the Eco-Tec Process using is a simple process Sludge separates from sewage Crystal clear sewage water.

The Eco-Tec Process does not involve any cumbersome machinery. Nor does it require continuous aeration. This results in considerable savings on infrastructural costs and power.

Similarly, for a very nominal cost, safe, bacteria-free drinking water can be made available through taps as is seen in developed nations such as the USA, Singapore, etc. This water is not only free of bacteria but is also free from chlorine, bleaching powder and alum compounds which are normally used in treating drinking water. This technology can be used for converting water obtained from unprotected ponds and lakes and from bore-wells to drinking grade at a very marginal cost.

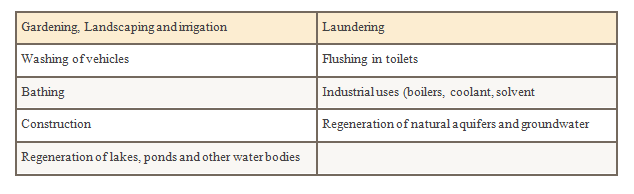

Water treated by the ECO-TEC process is of drinking grade. However, globally there is a mental block against consuming treated waste water, though such water is being used for drinking in countries like Japan and Singapore. Water treated by the ECO- TEC process is therefore suggested for all other secondary uses such as:

The Eco-Tec process can be employed for treating sewage and waste water in any of the following places where large quantities of sewage or waste water is generated:

-

-

- Municipal STPs

- Hospitals

- Hotels and resorts

- Apartment complexes and housing colonies

- Large office establishments

- Schools, colleges and educational institutions, especially those with hostels

- Industrial units producing waste water

-

sources like rivers, lakes, tanks and ponds becoming progressively converted into cesspools of sewage. Traditional sources of fresh water like rivers, lakes and ponds have become polluted with a combination of untreated sewage, industrial effluents, outflow from leather tanning units, effluents from sugar mills, paper mills and textile units, wastewater from fish processing units, etc with dangerous levels of bacteria and a multiplicity of toxins that it is unfit for washing or irrigation, let alone drinking..

ECOHEALTH PRODUCTS PVT LTD has developed the ECO-TEC PROCESS, an eco-friendly technology that makes use of herbal extracts for treating sewage,wastewater and several forms of industrial effluents and converting them into water fit for re-use. This technology can also be used for treating potable water to ensure that it is absolutely safe, germ-free and truly fit for drinking. The additional expenditure incurred in implementing this process can be more than justified by the substantial improvement in public health and the drastic reduction in the cost of medical expenditure.

The ECO-TEC PROCESS is a very simple process for treating sewage using organic reagents to convert it into potable grade.The process consists of two simple steps :

-

-

- Organic solid waste digestion, and

- Flocculation, sedimentation and disinfection rolled into one.

-

The water thus purified, after filtration through sand and carbon filters is odour-free, clear and free of harmful bacteria like E-coli and Salmonella. It is absolutely safe for re-use. The ingredients also have the unique property of de-scaling pipes. As such, it makes this treated water ideal for industrial use, particularly in boilers and AC plants.

The sludge is minimal and whatever sludge gets precipitated can be pumped out, dried and used as a very effective nitrogenous manure.

The process involves the use of :

-

-

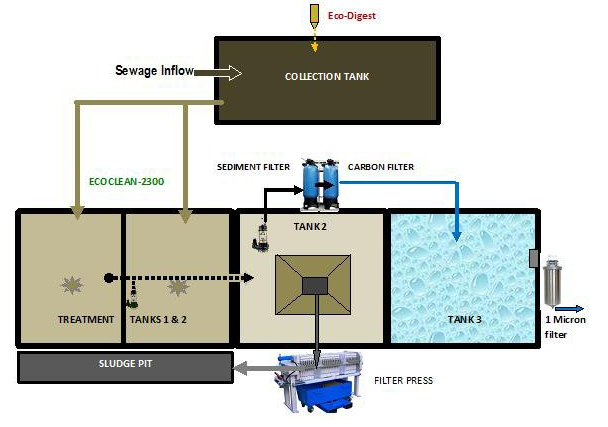

- ECO-DIGEST:An organic sludge digester that destroys 80% of the solid wastes in the sewage, while controlling the foul odour caused by gases like Hydrogen Sulphide, Ammonia and Methane. The dosing required is marginal – 5 ppm. One litre is good to digest 2,00,000 litres of sewage.

- ECOCLEAN-2300:A proprietary reagent prepared from herbal extracts that flocculates and sediments sludge within minutes of dosing while also eliminating all the harmful bacteria.

-

ECOCLEAN-2300 is a unique combination of the extracts of Azadirachta indica (Neem), Moringa olifera (Drumstick), Strychnos potatorum (Cleaning nut), Occimum sanctum (Tulsi) and Melaleuca alternifolia (Tea Tree oil) blended together using organic solvents and stabilizers. Dosed at 40 ppm (40 ml for 1000 litres of sewage), it not only induces flocculation and causes separation of both suspended and some dissolved solids but also disinfects the water, freeing it from all harmful bacteria including faecal coliforms and E-coli. One litre of ECOCLEAN-2300 is good to treat 25,000 litres of sewage.

Once filtered through a disc filter or a combination of sand and activated carbon filters, the treated water is fit for re-use. Being of botanical (herbal) origin, the reagent and the treated water are totally non-toxic and safe. They have no unpleasant taste or irritating smell.

Implementation of the Eco-Tec Process using Eco-Digest and Ecoclean-2300 is a simple process and is explained by the following diagram :

Both Eco-Digest and Ecoclean-2300 are extremely potent and dosing can be done in micro-quantities, making Eco-Tec Process one of the most cost-effective. Eco-friendly water treatment options available.

The Eco-Tec Process does not involve any cumbersome machinery. Nor does it require continuous aeration. This results in considerable savings on infrastructural costs and power.

Similarly, for a very nominal cost, safe, bacteria-free drinking water can be made available through taps as is seen in developed nations such as the USA, Singapore etc. This water is not only free of bacteria but is also free from chlorine, bleaching powder and alum compounds which are normally used in treating drinking water.

This technology can be used for converting water obtained from unprotected ponds and lakes and from bore-wells to drinking grade at a very marginal cost.

Water treated by the ECO-TEC process is of drinking grade. However, globally there is a mental block against consuming treated waste water, though such water is being used for drinking in countries like Japan and Singapore. Water treated by the ECO-TEC process is therefore suggested for all other secondary uses such as:

-

-

- Gardening, landscaping and irrigation

- Laundering

- Washing of vehicles

- Flushing in toilets

- Bathing

- Industrial uses (boilers, coolant, solvent)

- Construction

- Regeneration of natural aquifers and groundwater

- Regeneration of lakes, ponds and other water bodies

-

The Eco-Tec process can be employed for treating sewage and waste water in any of the following places where large quantities of sewage or waste water is generated:

-

-

- Municipal STPs

- Hospitals

- Hotels and resorts

- Apartment complexes and housing colonies

- Large office establishments

- Schools, colleges and educational institutions, especially those with hostels

- Industrial units producing waste water

-

Retrieves 98% of the waste water for re-use. A huge 98% saving on precious fresh water. Allowing for the mental block to drinking treated sewage, the water can be used for :

-

-

- Gardening

- Irrigation

- Flushing

- Laundering

- Washing of floors, vehicles, etc

- Industrial uses particularly in AC plants and boilers

-

Extremely effective process at very economical costs.

The ingredients used in the manufacture of the reagents are all of herbal origin. Organic, non-toxic, safe and with no side-effects.

Can easily be structured into existing STPs with minimal infrastructural changes.

Does not require elaborate network of aerators, blowers and other gadgetry.

Non-power-intensive process.

Totally eliminates all harmful bacteria, particularly the most difficult E-coli, which is the cause for a large variety of water-borne disease particularly in children of developing nations.

The residual effect of disinfectant ensures days of bactericidal action. Re-contamination does not happen for days.

Very versatile process – Can be used for sewage treatment, drinking water,swimming pools, lakes, ponds and reservoirs, rivers and desalinisation plants.

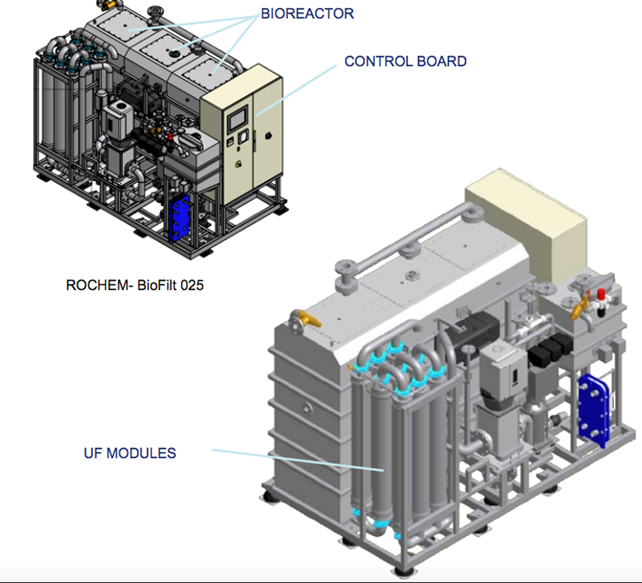

Memeco NV Group Rochem Sewage Systems

a Cala Casa India partner

a Cala Casa India partner

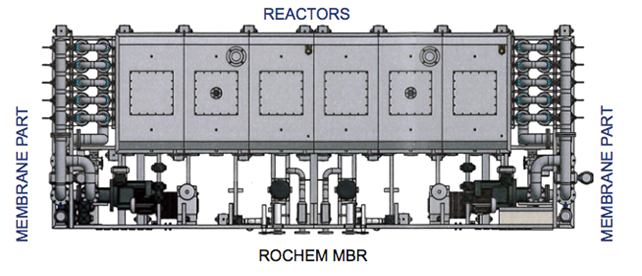

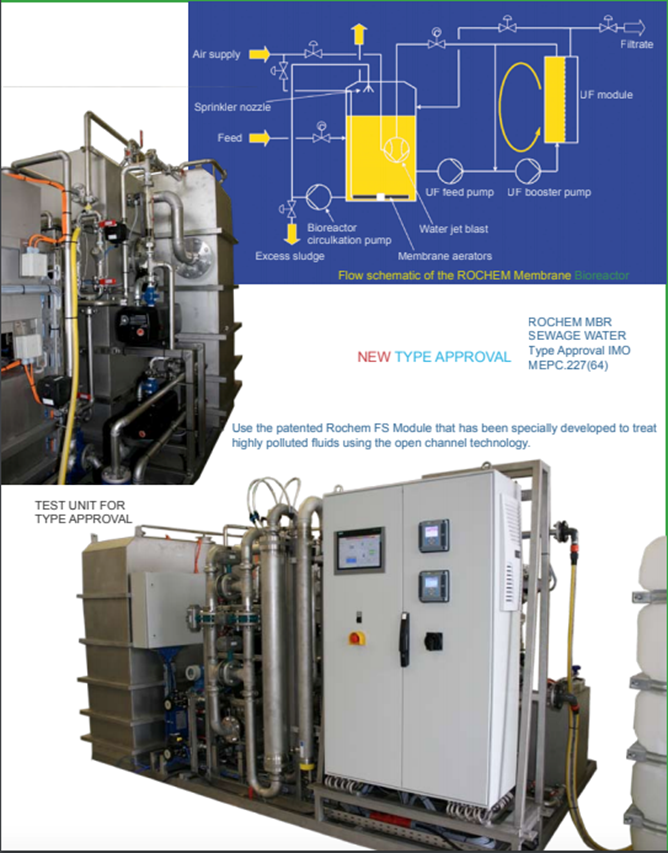

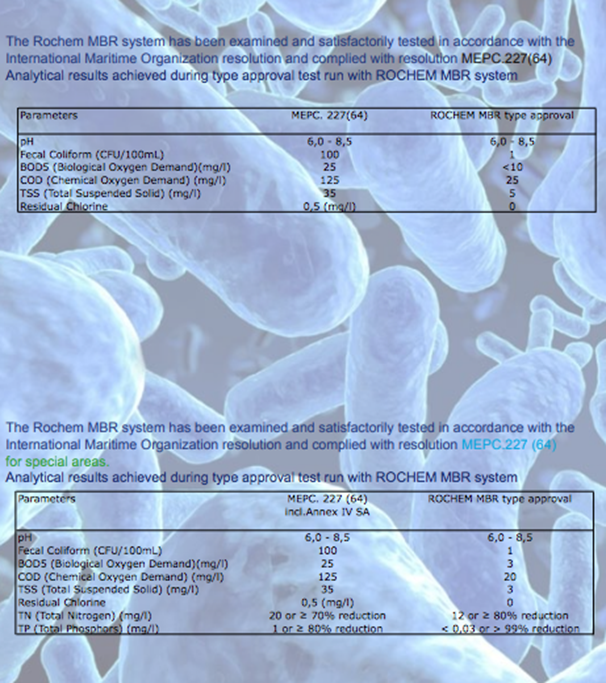

Memeco NV Group Rochem and ROCHEM Technical Services develops and builds advanced and highly efficient sewage treatment systems certified for municipal and commercial sewage based on the membrane bioreactor (MBR) technologies. The Advanced Wastewater Treatment (AWT) plant is designed to process black and grey waters.

Memeco NV Group Rochem MBR Membrane Bioreactor Turn sewage from toilets and grey waters from sinks, basins, showers, kitchen and laundry into clean environmental – friendly water that meets the bath water quality according to EU-standards.

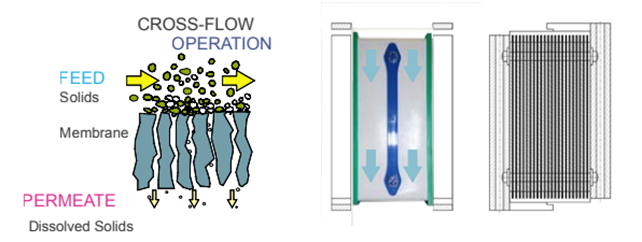

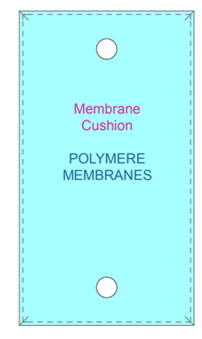

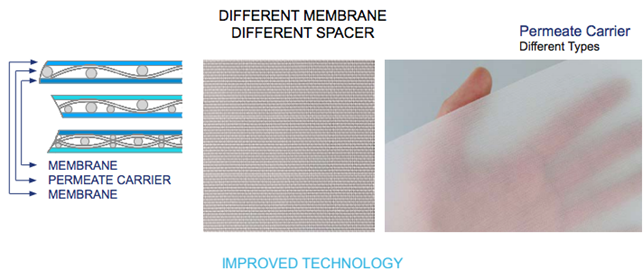

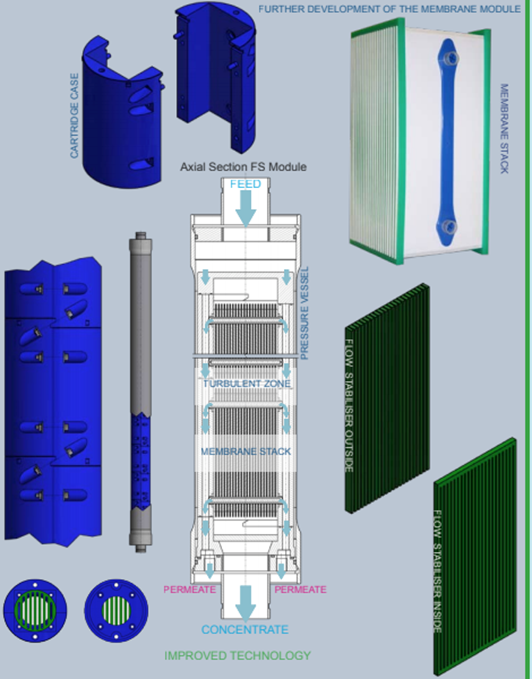

Improved technology for water purification with Memeco NV Group Rochem MBR The combination of a high density biomass reactor with the FS module system for ultrafiltration forms the operating unit of the Memeco NV Group Rochem membrane bioreactor which provides many advantages for sewage water treatment Memeco NV Group Rochem SOLUTION The high efficiency design of the membrane biological reactor purifies black water to achieve a superior quality to the international limit values for contaminants. Therefore, the environmentally sound purified waste water can be discharged allowed by any law.

Memeco NV Group Rochem Technical Services

The main components of the Memeco NV Group Rochem black and grey water treatment plant are the bioreactor segments and the ultrafiltration modules which form an elegant combination of the widely applied activated sludge process with the more sophisticated open-flow, ultrafiltration (UF) membrane separation process. Before entering the plant, the black and grey water influent passes a pre-filtration for rejecting particles and fibres. The filtrate is generated through pressurised cross flow on the membrane surface so that the suspended solids and bacteria are removed by the UF membrane. The continuous cross flow generate an optimised cross flow velocity on the membrane surface which scours the surface and removes deposits so that a continuously high flux rate is assured. The introduction of air/oxygen through air diffusers installed at the bottom of the reactor is necessary for the aerobic biological degradation of organic wastewater contaminants. The biowaste/excess sludge produced from the aerobic digestion of the black and grey water contaminants is collected in a sludge tank for disposal or further treatment. The bioreactor works as aerobic stage with a high biomass density. The biomass density can be increased up to 20 g/l by recirculation of the biomass through the Memeco NV Group Rochem FS modules.

In normal operation, a range between 14 and 16 g/l is typically sufficient for biodegradation. The required oxygen is supplied by blowers which are connected with the fine bubble diffusers installed at the bottom of the aeration tanks. The exhaust gas is discharged into the atmosphere via an exhaust line free of back pressure. The biomass concentration is monitored on-line with an optical sensor and kept constant by automatically controlled removal of sludge from the reactor. The waste-sewage-water processed in the Memeco NV Group Rochem MBR about 94-97% can be reused as technical water.

In order to protect the microorganisms from extreme pH values or high salinity, the pH and conductivity in the feed and in the FS loop have to be controlled. If one of the limit values is exceeded, the system has to be stopped and the feed water has to be discharged to the ships biowaste tank or the feed has to be adjusted to the right values. The waste water has to be collected in an equalising tank. From the equalisation tank, waste water is mechanically cleaned by a vibrational sieve.

The self cleaning vibrational sieve separates solids bigger than 100-150 µm from the influent stream. The pre-filtration is necessary to remove high loads of solids or fibers (like hair and paper waste) which cannot be biodegraded and could block the UF modules. The pre-filtered influent is pumped into the bioreactor section. The solid contaminants from the pre-filtered water are collected in a small tank and mixed with excess sludge for disposal or further treatment.

ROCHEM FS modules have been developed especially for the separation of bacteria, viruses and fine solids from water and waste water with high fouling potential. Most importantly, these modules exhibit low specific energy consumption at high and steady-state production. Ultrafiltration is based on porous membranes. Particles larger than the pore size of the membranes are rejected. In practice even smaller particles are rejected because of the selectivity of the filter cake (gel layer) on the membrane surface. Ultrafiltration membranes form an absolute barrier for bacteria and viruses.

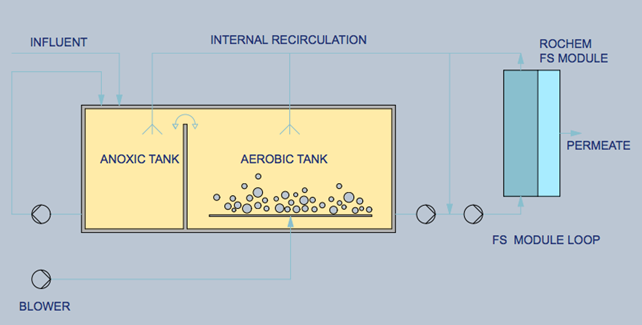

The function of the bioreactor is monitored by two parameters: – Dissolved oxygen concentration (DO) – Biomass dry weight (MLSS) At start-up, the DO is in approximate equilibrium with air, at a value of 7–8 mg O2 /L. Moving towards the nominal operating mode, it decreases to 1–2 mg O2 /L, indicating the microbial oxygen consumption. The oxygen demand varies with the flow rate and composition of the sewage feed. In order to remove nitrogen biologically through nitrification and denitrification, concentrate from the UF filtration loop is recirculated to the denitrification tank (anoxic tank). During the anoxic period, bacteria use the oxygen from the nitrate and convert it into nitrogen gas, which will be discharged through ventilation. NH3 + 2O2 => NO3- + H+ + H2O (Nitrification) 2NO3- + 2H+ => N2 + 5 [O] + H2O (Denitrification) In order to remove phosphorus, chemical phosphorus removal was applied. Iron salts and aluminum salts can be used for phosphorus removal.Fe(PO4) or Al3+ + (PO4)3+ => Al(PO4).

The Memeco NV Group Rochem advanced waste water treatment system offers the following advantages over other competitors and conventional waste water treatment processes: – Excellent effluent quality compliant with MEPC227(64) including Special Areas – High membrane permeability and durability – Long membrane life span – High flux due to the special membrane properties and cross flow effect – Low footprint due to the high content of biomass in the reactor (1.5 times higher than submerged MBR) – Compact and extreme robust design of the MBR system – Easy operation due to fully automatic system – Fully automatic membrane chemical cleaning with less personal involvement and no bad smell in com parison to submerged MBR-combination of a high density biomass reactor with the UF module system for ultrafiltration forms the operating unit of the Membrane Bio Reactor Memeco NV Group Rochem MBR which gives many advantages for waste water treatment.

Plug & play start-up

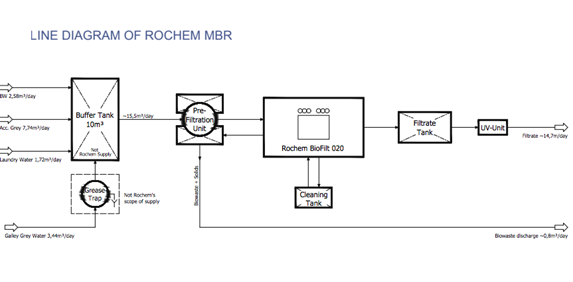

Line Diagram of ROCHEM MBR

Memeco NV Group Rochem Solution

The efficiency of the Membrane Biological Reactor allows for the purification of black water to achieve a quality superior to the international limit values for contaminants. Therefore, the environmentally sound purified waste water can be discharged in any area.

The Memeco NV Group Rochem Group have developed systems that are ahead of the Marpol certificate standards.

The Kriav Rochem Membrane Bio Reactor (MBR) is designed to treat combined Black & Grey waste waters from sewage, galley, accommodation and laundry grey waste waters.

The process in principle is essentially the same to simplify changing the number of bioreactors and membrane modules to suit the waste water volume.

The main components of the combined black and grey water treatment plant are the pre-filtration stage, bioreactor segments and the ultrafiltration modules. The clean effluent (filtrate) is passed to a small tank for further use or discharge. The bio-waste/excess sludge produced in the aerobic digestion of the black- and grey-water ingredients is collected in a bio-waste tank for disposal or further treatment such as drying and or incinerating, etc.

Design and Construction Standards

The Memeco NV Group Rochem RO Fresh Water Generators are designed, fabricated and approved according to the following National and International Standards:

- DIN – (German Industrial Standard)

- VDE – (Association of German Electricians)

- VDMA- (Organisation of German Mechanical Engineers)

- IEC – International Electric Standards for Electric Motors

- ISO – International Standards

The Memeco NV Group Rochem RO units are designed and constructed to fulfil the requirements of the following Classification societies:

- Germanischer Lloyd

- Lloyds Register of Shipping

- American Bureau of Shipping

- Det Norske Veritas

- Bureau Veritas

- RINA Certificates for high pressure hoses